Här pratar jag och Viktoria med Thomas Bjelkeman-Pettersson och Linnea Jäder i podden Matkretslopp om vår syn på insekters roll i våra livsmedelssystem.

Blog from the Environmental Engineering Research Group at SLU

Här pratar jag och Viktoria med Thomas Bjelkeman-Pettersson och Linnea Jäder i podden Matkretslopp om vår syn på insekters roll i våra livsmedelssystem.

In this review, published in Animal, Karol B. Barragán-Fonseca, Daipiero Gómez, Daniel Dzepe, Shaphan Y. Chia and I (Cecilia Lalander) investigate the current state of black soldier fly larvae (BSFL) farming in the global south. We surveyed as many producers we managed, and were able to collect data from 33 of the 100 producers we contacted: 14 in Africa, 4 in Latin America, and 15 in Asia. The review highlights the potential of Black Soldier Fly (BSF) farming has in the Global South as a sustainable solution for food production and organic waste management. By converting waste into valuable products such as animal feed and organic fertilizer, BSF farming aligns with the principles of a circular economy and supports sustainable development goals. The study emphasizes the region’s strengths, including favorable climatic conditions that reduce resource inputs and a long tradition of entomophagy, which facilitates cultural acceptance of insect farming. Smallholder farmers play a vital role in this emerging sector, and BSF farming offers them economic opportunities, such as reducing feed costs for livestock and aquaculture.

Despite its promise, the sector faces significant challenges. Producers encounter regulatory gaps, making it difficult to ensure compliance and market their products. Securing a stable supply of high-quality waste substrates is another major hurdle, while scaling up operations is constrained by technological and financial barriers. These challenges are further exacerbated by competition from conventional feed sources such as fishmeal and soybean meal, which are frequently more cost-effective.

Regional variations also influence the development of BSF farming. For instance, African producers use diverse organic waste substrates, while Asian producers tend to avoid manure due to cultural resistance. Latin America, by contrast, has fewer established facilities and producers, likely due to lower familiarity with insect farming and less institutional support.

The review underscores the growing market demand for BSF products, especially for animal feed and pet food. However, to fully realize the potential of BSF farming, there is a need for global collaboration among policymakers, researchers, and the private sector. Efforts to establish consistent regulations, improve waste substrate logistics, and develop scalable technologies will be critical for overcoming these barriers. If you are interested, read the full review here.

As usual did we participate in the science festival SciFest here in Uppsala, approximately 7000 persons, mainly pupils from grades four to nine, visited the SciFest during the three days where we showcased the practical parts of our research with the fly larvae and the urine based fertilizer production. Many of the visitors was interested and some had hard time to see the big amount of larvae in one place. The urine fertilizer was not as public magnet but still appreciated by many visitors, so we hope that the coming generation will adopt these technologies as part of a future more sustainable society.

Over the last year, the BSF group has conducted exciting experiments as part of the Happy Salmon project. We received big batches of two species of macroalgae (Ulva and Saccharina) for the Nordic SeaFarm in Dingle, to be used as feed substrate for rearing BSF larvae. The algae was mixed with brewery spent grains, provided by Train Station Brewery in Knivsta and vegetable waste, ensuring a nutritiously balanced diet for the larvae. Interestingly, the larvae grew quite well in this blend substrate and achieved a high body protein (40%), while the fat content was considerably lower than our larvae usually are (< 15%), making this larval biomass a good feed ingredient.

The frass fertilizer obtained in these experiments also had interesting properties, having > 80% of organic matter and a NPK ratio of 3/1/3. However, the most exciting results regarding this frass fertiliser was the composition of beneficial microorganisms, stimulated by the presence of the algae in the larval diet. Moreover, the frass container plant hormones, including auxins, gibberellins and cytokinins, which are important regulators of plant growth and metabolism. These novel results are being investigated and assessed now to see how different plant species can benefit from frass when it is applied in the soil.

As a next step, the larvae produced with the macroalgae and brewery spent grains are being pressed and defatted, and then used as a nutritious feed ingredient for the production of fish feed. Skretting, a global leader in sustainable aquaculture nutrition, in Norway will use this feed in salmon growth trials. We believe that this BSF larvae-derived ingredient can be considered a more sustainable feed ingredient for aquaculture. Fingers crossed for interesting results to come!

The seminar is given in English and can be seen here.

On Thursday the 12th of September at 12:15 pm CET, Cecilia Lalander will tell her view on the matter. Tune in! It will be available online afterwards if you don’t have time to watch live.

Worth knowing is the SLU University Library’s popular science lunchtime lecture series. Here, exciting and recent research results from SLU are presented. We offer a light lunch, and after the lecture listeners have the opportunity to ask questions.

Our recent study explores an innovative approach to sustainable agriculture by combining dehydrated human urine with various organic wastes to create circular fertilizers. This research addresses a critical need: reducing reliance on inorganic fertilizers while managing nutrient cycles more effectively. By tailoring these fertiliser blends to meet the specific macronutrient demands of 15 major crops, we aim to provide a viable alternative that supports both crop yields and environmental sustainability.

We used a reverse blending modeling approach, analyzing data from 359 different organic wastes to simulate potential fertilizer combinations. The challenge was to identify materials that could balance the nutrient profile of dehydrated human urine, which is naturally high in nitrogen but lower in phosphorus and potassium. Through this process, biochars and ashes emerged as particularly promising blending materials due to their low nitrogen content and higher levels of phosphorus and/or potassium. This made them ideal for pairing with human urine, which helped offset the typical nutrient imbalances when used alone.

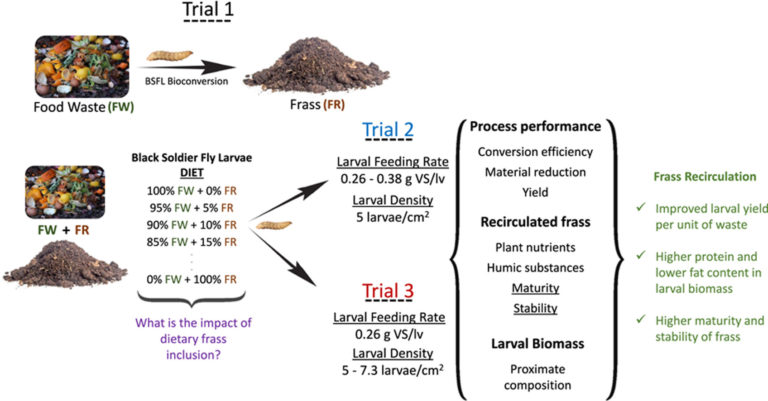

In our article Recirculating frass from food waste bioconversion using black soldier fly larvae: Impacts on process efficiency and product quality recently published in the Journal of Environmental Management, we showed that food waste-derived frass, an unstable fertilizer with phytotoxic properties when used fresh, can be reused in the bioconversion process as part of the larvae’s feed. This approach offers several benefits for both the process and the quality of the resulting larval biomass and frass fertilizers.

Several studies reported phytotoxicity (adverse effects on plant growth, physiology or metabolism cause by several different substances) in frass from black soldier fly larvae (BSFL), especially when growing crops in greenhouses and using frass as a fertilizer or growing media. We believe that this phytotoxicity is related to the fact that waste bioconversion with BSFL is very rapid (< 14 days), and that there therefore is no time for the organic matter to be stabilized. Stabilizing this “fresh” frass’ organic matter is crucial for its safe use as a fertilizer or soil amendment. However, studies have shown that the post-composting of frass can be the major source of greenhouse gas emissions and increase the overall environmental impact of this treatment. Finding a more viable and sustainable way of stabilizing fress frass was the main goal of this study.

The hypothesis of the study was that a significant portion of the organic matter in food waste-derived frass remains relatively undigested, allowing the BSFL to further consume and digest it, thereby increasing the degree of decomposition. This hypothesis was confirmed, as the frass produced after consuming the food waste with frass inclusion (called recirculated frass) had a lower organic matter content than the fresh frass. In addition, several characteristics of the recirculated frass pointed towards higher maturity and higher stability, which indicates that it is safer to use as fertilizer. Interestingly, not only the resulting frass, but also the larval biomass was positively affected with this frass recirculation process. A significant correlation of larval biomass composition and frass-inclusion rate was establisheda, showing that as frass inclusion increased, the larval biomass had higher protein content and lower fat content. Considering that protein ingredients are the most expensive input in animal feeds, this is likely to be of interest to the insect industry.

One of the most intriguing findings of this study was that recirculating frass back into the bioconversion process significantly increased the larval yield per unit of waste. This indicates that incorporating fresh frass into the larvae’s diet allows for a higher biomass of larvae using the same amount of waste. This innovative method for enhancing both the process and product quality is highly promising. We are now developing new studies on frass recirculation to better understand the underlying mechanisms and explore any additional benefits this approach may offer.

Hello! My name is Chibambila Simbeye, and I am thrilled to introduce myself as a new member of the SLU Urine Research Group. I hail from Chingola, a small mining town in the Copperbelt province of Zambia. My background is in civil engineering. I hold both a bachelor’s and a master’s degree in this field, with my master’s focusing on water engineering. For my master’s thesis, I explored the recovery of phosphorus from human urine in the form of vivianite. This further fueled my interest and passion for innovative sanitation solutions.

At SLU, my research will focus on developing alkaline urine dehydration technology for decentralized sanitation systems. I am optimistic that the results of my research will be adopted and implemented to improve sanitation practices around the world. If you have an interest in urine treatment or water and sanitation, I would love to exchange ideas with you.

Why do I do what I do? I firmly believe that access to sanitation is a basic human right that remains unfulfilled in many parts of the world, particularly in developing countries. Urban sprawl has led to the growth of large unplanned settlements where traditional centralized sanitation systems are often unfeasible. I am convinced that decentralized systems, which incorporate source separation, are the key to addressing these challenges sustainably. To achieve this, we need to understand how to manage each waste fraction effectively, with urine being a crucial component.

In addition to my academic pursuits, I am a computing tech enthusiast and an avid fan of competitive sports, especially football and I am always up for a football discussion. I also like to play chess occasionally, so feel free to reach out if you’d like to have a game!

Looking forward to connecting with you all and contributing to the exciting work happening at SLU.

Kale Bwangu! (Direct translation: long ago fast, Meaning: Already done and used a confident salute for mutual understanding)

My name is Christoffer and I started working here in September 2023 as a PhD student. The field of research I work in is turning urine from urine diverting toilets into a dehydrated, commercial fertilizer. Urine diverting toilets commonly have problems with precipitation forming, clogging the pipes. The scope of my research is to investigate this process and come up with solutions so that the pipes can easily be kept clean, which would open up for wider implementation of those toilets.

My background is in Environment & Water Engineering, which I studied here in Uppsala, my home town. I have been interested in research my whole life, and wanted to become a PhD student for as long as I knew of the concept. I am very curious and am at my happiest when I get to perform experiments and analyse the results.

Apart from research, my interests are many and varied. I sing and play a lot, both choir music as well as traditional Scandinavian & Celtic folk music. I nourish a passion for nature and love to go hiking. I am also very interested in languages, different cultures and history, and frequently discuss those topics with people from other countries as well as other swedes, preferably over a fika!