Insects as food and feed have, over the past decade, been lifted as a promising and sustainable solution to feeding a growing population. Yet despite years of innovation, the insect industry hasn’t scaled or established itself as expected.

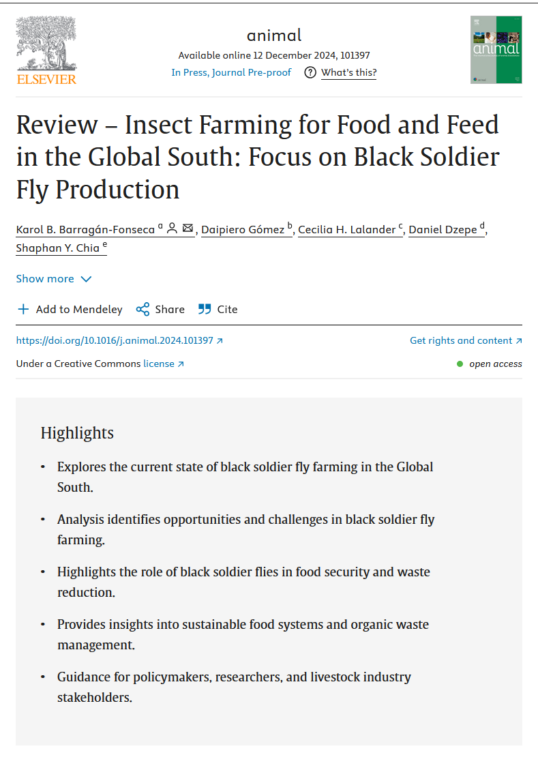

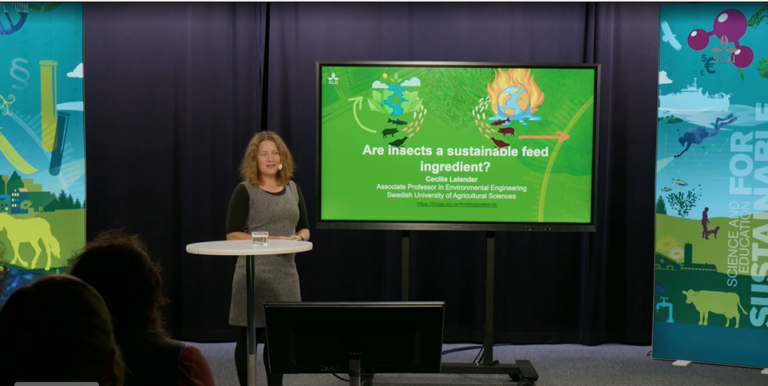

In a recently published Editorial in the Journal of Insects as Food and Feed, co-authored by Meghan Barrett, Laura Gasco, Christine Picard, Jeffery Tomberlin, Arnold van Huis — and from the Kretsloppsteknik group, Ivã Lopes and Cecilia Lalander — we highlight both the potential and the persistent challenges of the sector.

We point to key hurdles: integrating circular systems into existing regulatory frameworks in the Global North, ensuring safety in such systems, assessing allergen risks, mitigating biosecurity concerns linked to non-native species, evaluating the environmental safety of insect by-products, and addressing animal welfare. Or put differently, we aim to #WorkOutTheBugs of the insect industry.

We find evidence in litterature that insects offer strong potential — not only for food and feed, but also in waste management. We argue that the slow growth of the industry may not be entirely due to the technology itself, but rather a sign of the difficulties of running #CircularBusinesses in a largely linear economy.

To unlock the sector’s potential, we suggest that researchers, producers, regulators, and consumers need to continue collaborating, remain open to new knowledge, and advocate for policy frameworks that support a transition toward true #CircularFoodSystems.